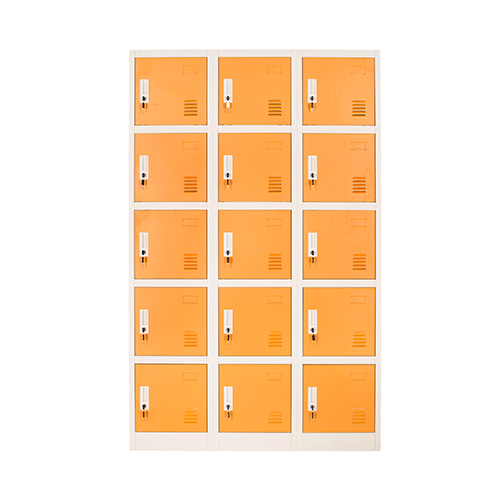

3 Line 15 Doors Locker

Model:3L-B5

- Size:W900*D450*1850mm /CUSTOMIZED

- MOQ:30

- Packing Volume:0.172cbm

- Thickness:0.5mm-0.9mm

- Structure:Knock Down

- Raw Material:Cold Rolled Steel

- Surface:Electrostatic Powder Coating

- Business type:B2B

- Product Description

- Accessories & Packing

- QC System

Main Features

● Name Tag: Used to put in category remark for different sorts of document

● Cyber lock from Thailand

● Cushion is used to reduce the friction and noise

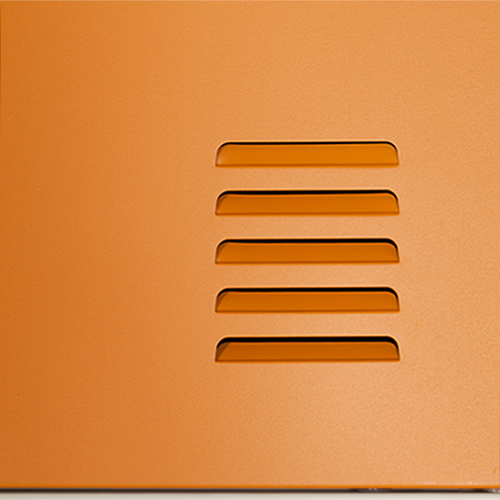

● Ventilation hole avoid moist

● Reinforcing rib welded on back of doors

● Lock: Cyber Lock from Thailand

● Application: Office, School,Government,Hotel etc

● Delivery Time: 30days after payment

● Certificates: ISO9001, ISO14001, OHSAS18001, China Environmental Labelling

● Thickness of painting: 60μm

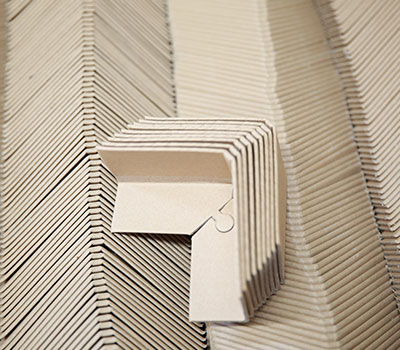

● Packing Method: flat packed,foam board,foam paper,standard 5 layers carton,packing straps

● Warranty: 5 years

Main Technical Parameters

|

Size |

W900*D450**H1850mm |

Structure |

Knock Down |

|

Packing Volume |

0.172cbm |

Raw Material |

Cold Rolled Steel |

|

Thickness |

0.5mm-0.9mm |

Surface |

Electrostatic Powder Coating |

|

MOQ |

50pcs |

Color Options |

RAL,Pantone,Customized |

MATERIALS AND COLOUR

PACKAGE

Step 1 Pre-assembling before painting

In the sheet metal workshop, when sheet metal part is finished, QC department will assemble the metal parts and check size, edge,welding point,bending,integral assembly effect etc.

Step 2 Powder coating test

After panting,the painting group will check powder uniformity, surface flatness ,chromatic aberration etc. Unqualified parts will not have a chance to go to the next stage.

Step 3 Assembling before packing

After painting but before packing, QC department will assemble all the parts again to do the comprehensive inspection, including structure, size, accessories, color etc.

Step 4 Spot check in warehouse

Before loading, QC department will do the random inspection for the products in the warehouse, ensure the quality again before products leave factory.