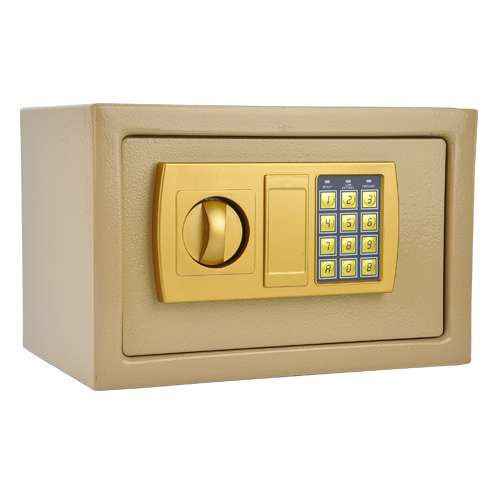

Safe Box

Model:CBNT-SF-20E

- Size:W310*D200*H200mm

- MOQ:30 PCS

- Packing Volume:0.026CBM

- Thickness:Door 3mm & Body 1.5mm

- Structure:Assembled

- Raw Material:Cold Rolled Steel

- Surface:Electrostatic Powder Coating

- BUSINESS TYPE:B2B

- Product Description

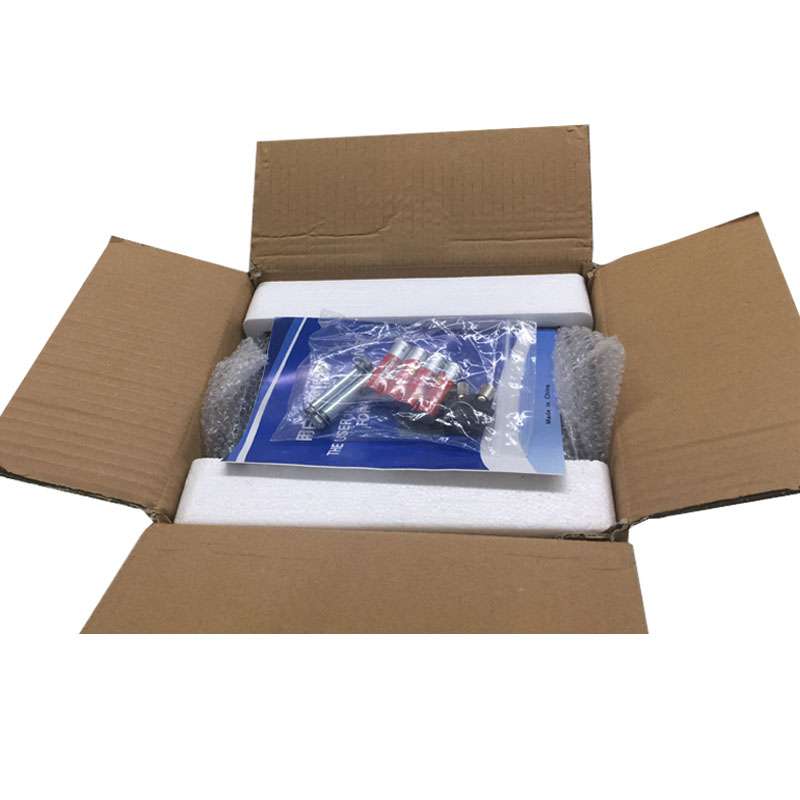

- Accessories & Packing

- QC System

Main Features

1. CE&ROHS Approved

2. High quality electornic lock : 3-8 digit user codes plus mechanical override keys

3. 3 Chrome plated solid steel locking bolts

4. Automatic locked for 5 minutes when 3 times fault password is input

5. Protective Floor Mat

6. 4 x AA batteries included, low battery warning

7. 4 pre-drilled anchor bolt holes, fixing kits supplied for anchoring to wall or floor, top opening for cash and coin

8. User manual included

9. Surface treatment: Powder coating against rust or corrosion

10.Three colors: white, black, gold

11.Two types: hole on the top/ no hole on the top

12.Door thickness: 3 mm Body thickness:1.5mm

13.Usually load 1010pcs in 1X20GP

● Application: Office,Home,Hotel etc

● Delivery Time: 30days after payment

● Thickness of painting: 60μm

● Packing Method: Assembled structure,foam board,foam paper,standard 5 layers carton,packing straps

● Warranty: 5 years

Main Technical Parameters

|

Size |

W310*D200*H200mm |

Structure |

Assembled |

|

Packing Volume |

0.026cbm |

Raw Material |

Cold Rolled Steel |

|

Thickness |

Door 3mm & Body 1.5mm |

Surface |

Electrostatic Powder Coating |

|

MOQ |

30pcs |

Color Options |

RAL,Pantone,Customized |

MATERIALS AND COLOUR

PACKAGE

Step 1 Pre-assembling before painting

In the sheet metal workshop, when sheet metal part is finished, QC department will assemble the metal parts and check size, edge,welding point,bending,integral assembly effect etc.

Step 2 Powder coating test

After panting,the painting group will check powder uniformity, surface flatness ,chromatic aberration etc. Unqualified parts will not have a chance to go to the next stage.

Step 3 Assembling before packing

After painting but before packing, QC department will assemble all the parts again to do the comprehensive inspection, including structure, size, accessories, color etc.

Step 4 Spot check in warehouse

Before loading, QC department will do the random inspection for the products in the warehouse, ensure the quality again before products leave factory.